3D printing solutions must know exactly which problems they’re trying to solve.

Thanks to recent advances in technology, design, and materials, the role of dental 3D printers is rapidly expanding from dental labs into individual practices. So how does this hyped-up technology actually work, and what about 3D printing makes it such a great fit for dentistry?

The adoption of dental 3D printers is driven by continuous innovation in three major categories:

Biocompatible Materials

Materials innovation is at the heart of dental 3D printer adoption. While the production of models is crucial for many practices, the creation of dental appliances that can be placed intraorally, such as night guards, surgical guides, and digital dentures, are critical to the advancement of this technology’s role in dentistry.

Dental 3D printers reached an inflection point when biocompatible materials became widely available for desktop machines. These FDA-compliant materials made 3D printed parts safe for intraoral use and offered great mechanical properties, propelling desktop 3D printers into dental practices all over the world.

Since the introduction of biocompatible materials for 3D printing in dentistry, the emphasis has been on improving mechanical properties to provide intraoral parts that have great strength and a high resistance to wear. Because materials innovations can come from anywhere, it’s important to choose a 3D printer that offers support for third-party materials.

Accuracy and Repeatability

Accuracy and repeatability are essential for dental 3D printers. In order to provide the highest standard of care and final fit and finish, extremely high accuracy is non-negotiable. Recent advancements in materials and printing technology have supercharged the accuracy of 3D printers.

One of the central requirements of dental manufacturing is very high accuracy and repeatable results. Bringing manufacturing of models and other appliances in-office only pays off if the technology can provide the tight tolerances required for fitted parts. But it isn’t enough for a single print to provide accuracy; the results need to be easily replicated over time. Though printers can be easily bucketed into categories based on the details of their underpinning technologies, these categories rarely tell the full story.

While many 3D printers on the market provide high theoretical accuracy, not all offer results that are repeatable over time. The hallmark of a true dental 3D printer is to have both high accuracy and repeatability. As 3D printing technology continues to mature, there is an emphasis on the way light is delivered to the build area to ensure accurate, repeatable results.

Production Speed and Scalability

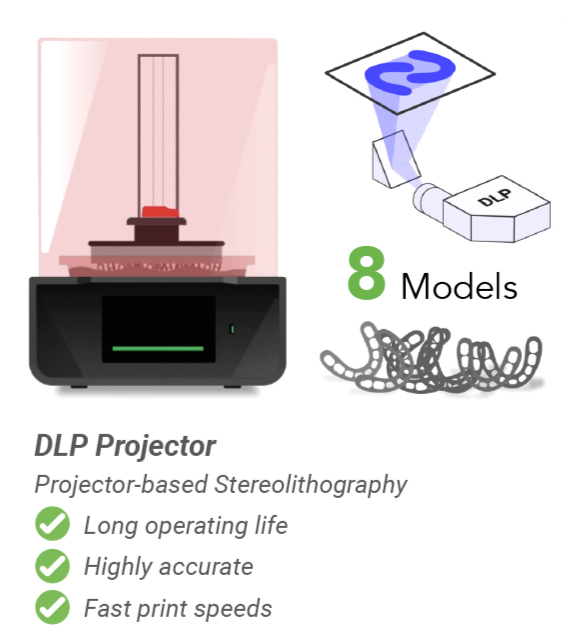

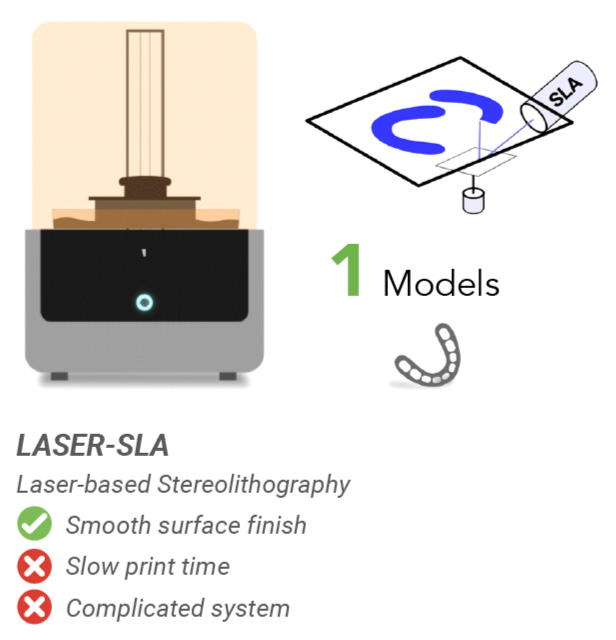

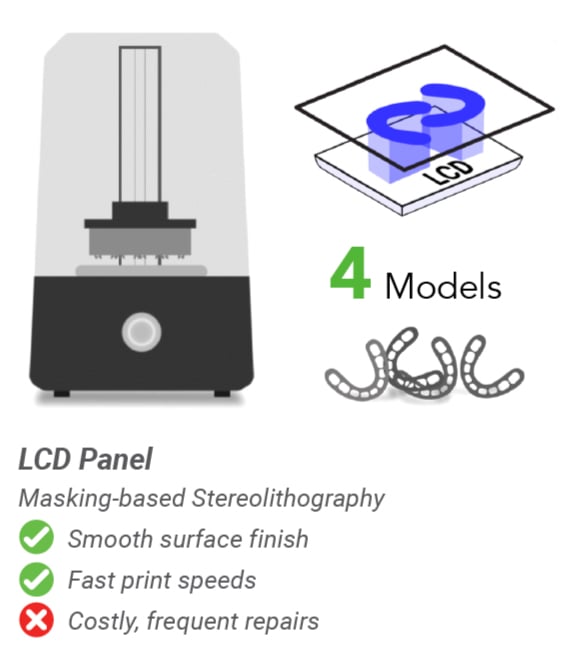

Same and next-day production of dental appliances is a longtime dream of digital dentistry, and dental 3D printers have the capacity to make this dream a reality. But while certain aspects of 3D printing technology have begun to converge, there is still a massive difference in production speed and scalability. A large portion of these discrepancies are motivated by the technology that underpins each printer type, but many are not.

While dental 3D printers are sometimes used for printing only one or two parts at a time, many cases require the rapid fabrication of a large number of parts. Clear aligner cases are the obvious standout, but batched nightguards, surgical guides, and denture bases all require large print volume as well. Emphasis of development in this region of the technology is focused on reducing both single-part as well as full-batch print speeds.

The 30-Minute Dental 3D Printer

Here’s why DLP is right for digital dentistry.

While the ability to produce dental appliances in-office is revolutionary to digital dentistry, the speed of an individual 3D printer can make a substantial difference. A practical way to measure the outcome of this speed is to measure its output via the 30-minute test, which shows both the on-demand printing speed as well as the overall throughput of the printer. DLP projectors can produce a full platform of dental arches in around 25 minutes.

The Current Landscape of Dental 3D Printing

3D printing in dentistry can be bucketed into two major categories. On one hand are the industrial-grade, high-throughput machines that feature huge capacity and good accuracy. While these machines are often a good choice for dental labs that create hundreds of appliances per day, their high upfront cost, large size, and maintenance requirements mean that they’re often an impractical solution for the needs of individual dental offices. Though they are a great companion in a high-volume lab, industrial 3D printers are prohibitively expensive, physically large, require expensive maintenance, and may require a background in 3D printing technology to operate.

Desktop 3D printers, on the other hand, feature excellent quality at a significantly reduced price and are packaged in a much more manageable size: not much larger than your average LaserJet paper printer. Desktop 3D printers are just as versatile as their larger counterparts but tend to feature smaller build platforms and lower overall throughput. For the general practitioner, oral surgeon, practicing prosthodontist or orthodontist, a desktop dental 3D printer with good throughput will supply more than enough capacity to satisfy high-volume offices.

Many companies are scrambling to add certified dental resin capabilities to their current 3D printer lineup. The simple fact of the matter is that 3D printing in dentistry is exploding. A cursory look at the most popular printers will give you the impression that any of their machines will dramatically improve your dental workflow. But many cannot print final dental appliances such as dentures, crowns, bridges, and indirect bonding trays. It’s important to look beyond just the up-front acquisition cost, because if it can’t produce a final printed dental appliance with certified biocompatible resin, its usefulness in dentistry will be limited.

Your source for Dental 3D Printers & Materials

Atlanta Dental can help you find the best fit for your practice!

For more information contact your sales representative or call 1.800.218.5412

![ADS logo RM[56] ADS logo RM[56]](https://news.atlantadental.com/hs-fs/hubfs/ADS%20logo%20RM%5B56%5D.png?width=640&height=222&name=ADS%20logo%20RM%5B56%5D.png)